In modern mechanical engineering and the automotive industry, the gearbox plays a crucial role as a vital power transmission system. Whether in cars, trucks, or industrial machinery, the operation of the gearbox directly impacts the efficiency and reliability of the equipment. Behind every gearbox lies a series of prec......

Product Series

Car Engine Gearbox Parts Manufacturers

-

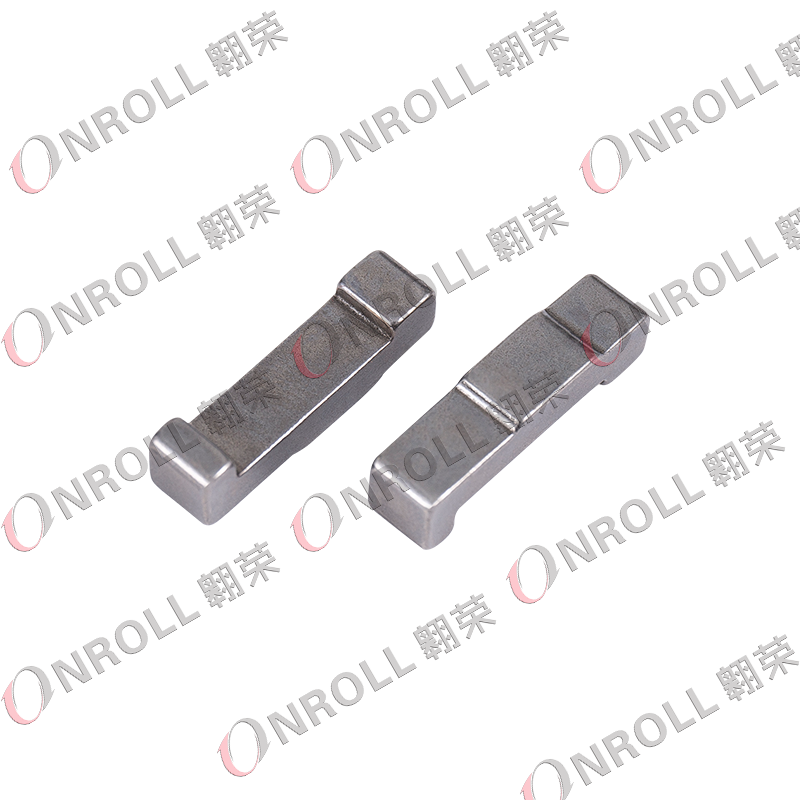

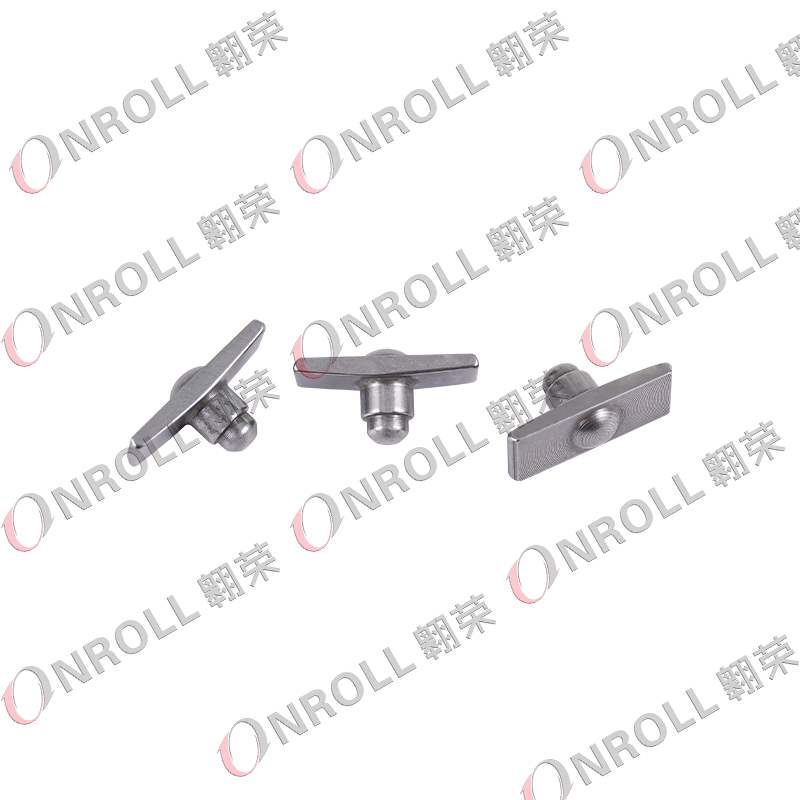

Isuzu 5th Reverse Synchronizer Slider

Cold-drawn processing sliders have high efficiency, low cost, mature and stable processes. The cost is close to powder metallurgy.

-

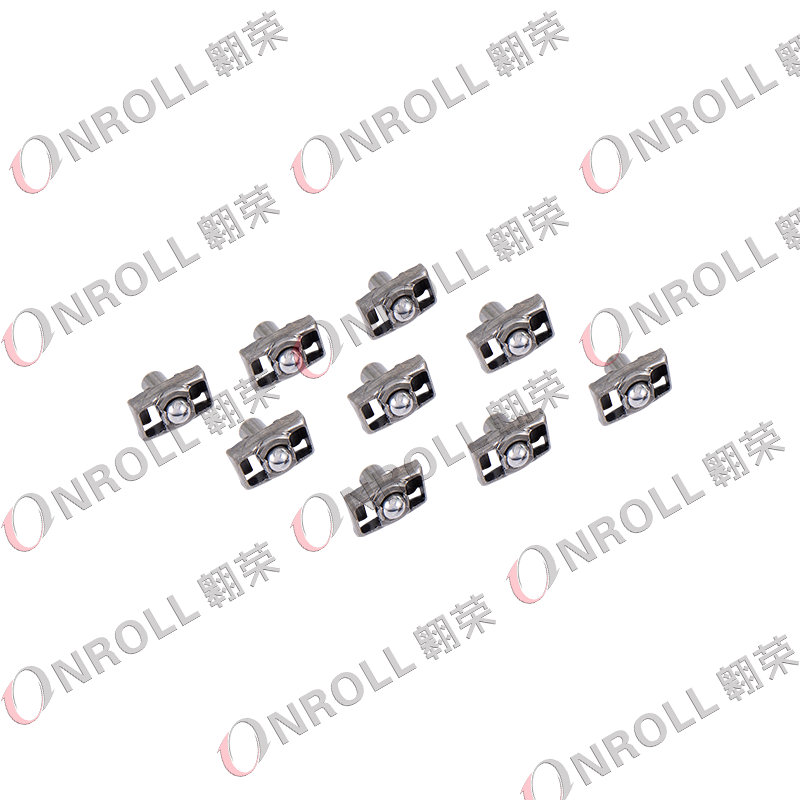

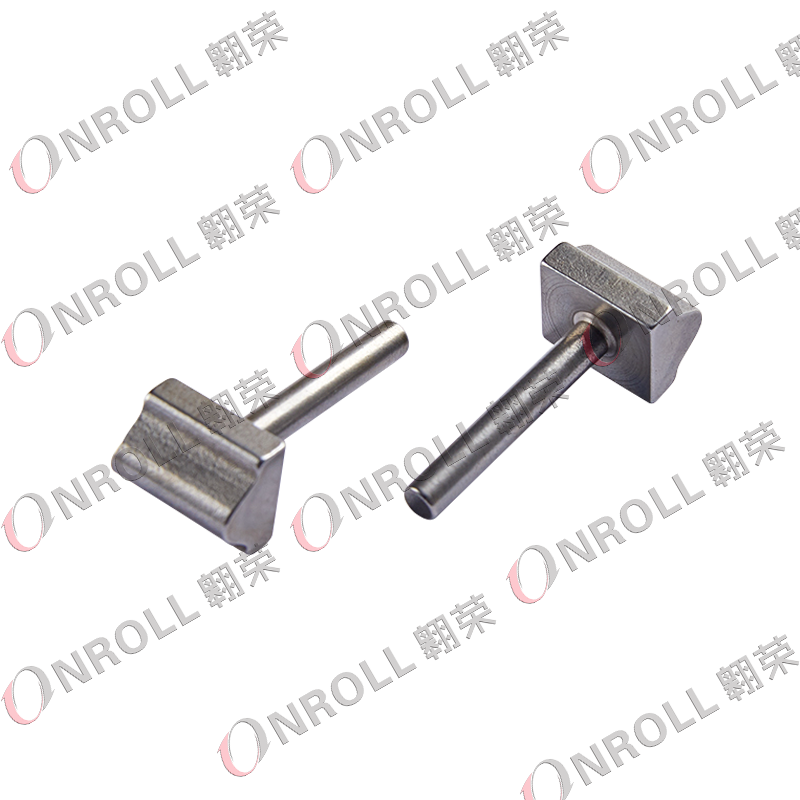

Synchronizer Guide Block Assembly

Cold drawing + machining technology retains the strength of steel parts while improving assembly convenience.

-

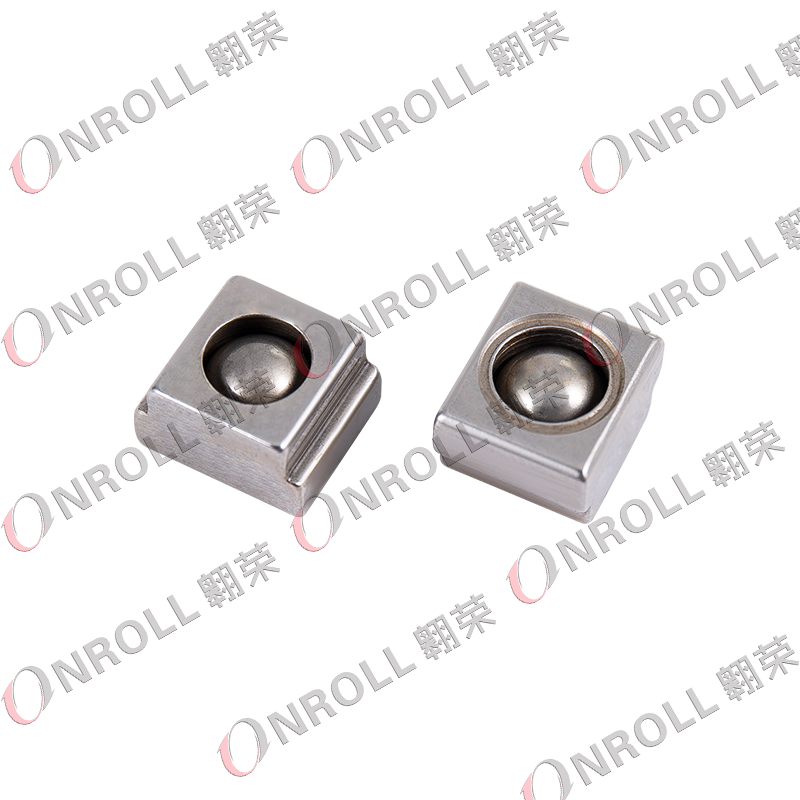

Synchronizer Guide Block Assembly

The stamping synchronizer slider and hollow structure reduce product weight. Solve customers' lightweight needs.

-

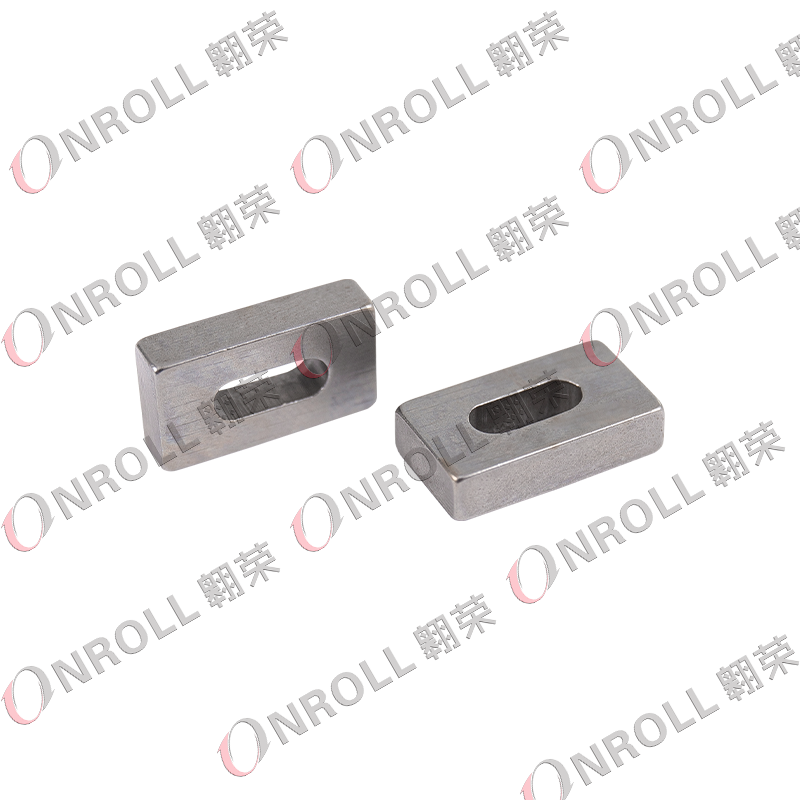

Synchronizer Guide Block Assembly

The car processing synchronizer slider is suitable for various complex structures and special-shaped structure sliders. Customizable.

-

Synchronizer Push Block

The cold heading process + machining can reduce costs and improve efficiency while retaining the mechanical strength of the slider.

-

Push Block

The cold heading process + machining can reduce costs and improve efficiency while retaining the mechanical strength of the slider.

-

Synchronizer Stop Block

The cold heading process is adopted, with high efficiency, stable dimensionality, and obvious cost advantages.

-

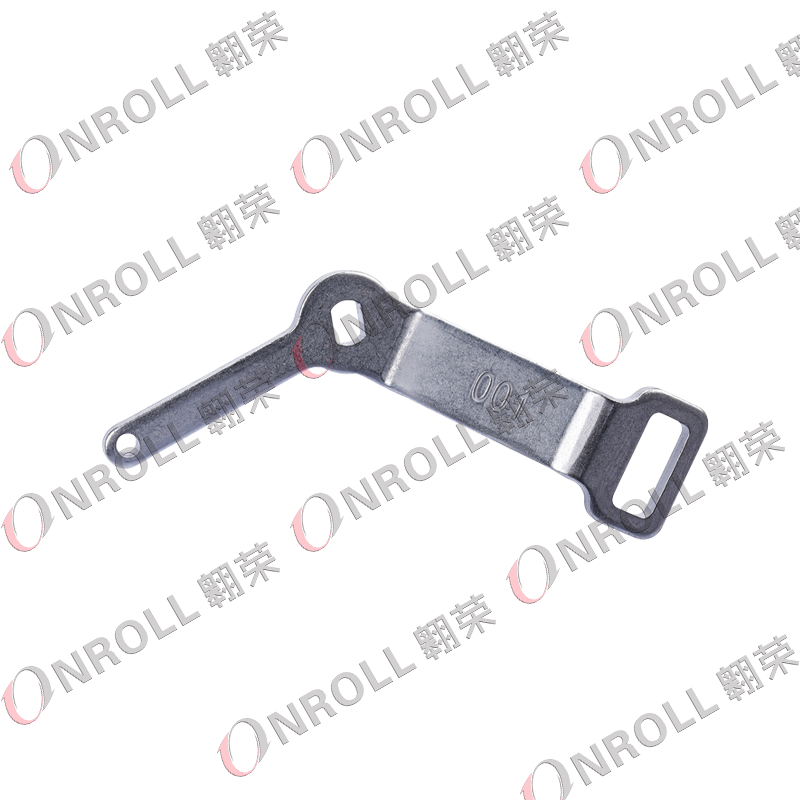

Harness Bracket

Continuous die stamping, bending molding, high efficiency, and stable dimensions. External electrophoresis paint anti-rust

-

Shifting Arm

The gear shifting arm processed in the stamping process has high efficiency and low cost.

Jiaxing OnRoll Machinery Co., Ltd.

Coming From China, Marketing To The World.

Jiaxing OnRoll Machinery Co., Ltd. is a private high-tech company specializing in the production of automobile synchronizer strut, transmission parts and brake system parts

The company's registered trademark is "OnRoll". The company covers an area of 4,000 square meters, and has passed IATF16949 quality system certification, with synchronizer strut automatic production equipment and automatic size, elastic testing equipment. We are Wholesale Car Engine Gearbox Parts Manufacturers and Car Engine Gearbox Parts Company, The first to complete the localization of the synchronizer strut , break the high-precision synchronizer strut rely on import, and gradually replace imported part, fill the domestic gap, synchronizer strut products basically cover domestic brands.

We can provide customers with an ideal solution from design to mass production. With the update of technology and process, we can reduce cost and increase efficiency for customers and provide cost-effective products.

The company adheres to sustained innovation, planning high-precision synchronizer guinea production lines, adapting to the development trend of domestic AT, DCT gearbox, and new energy vehicle intelligent linear drive control system, and constantly creates value for customers.

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

English

English  Español

Español  中文简体

中文简体