What Role Do New Energy Machinery Gearbox Accessories Play in the Future of Automotive Industry?

In the fast-evolving landscape of the automotive industry, the shift towards new energy vehicles (NEVs) has spurred a dramatic transformation in the machinery that drives these vehicles. One crucial component of this transformation is the gearbox, which plays a fundamental role in the performance and efficiency of both conventional and new energy vehicles. But what role do New Energy Machinery Gearbox Accessories play in ensuring that these systems are both high-performing and reliable? Let's explore this in detail.

The Evolution of New Energy Vehicles and the Need for Specialized Gearbox Components

As we transition from traditional internal combustion engines (ICE) to electric and hybrid powertrains, the requirements for automotive gearboxes have changed significantly. Unlike traditional gearboxes that focus on mechanical power transmission, gearboxes in new energy vehicles (NEVs) must handle the nuances of electric and hybrid systems, offering higher efficiency and smarter control systems. New Energy Machinery Gearbox Accessories play an essential part in ensuring that these advanced systems perform optimally.

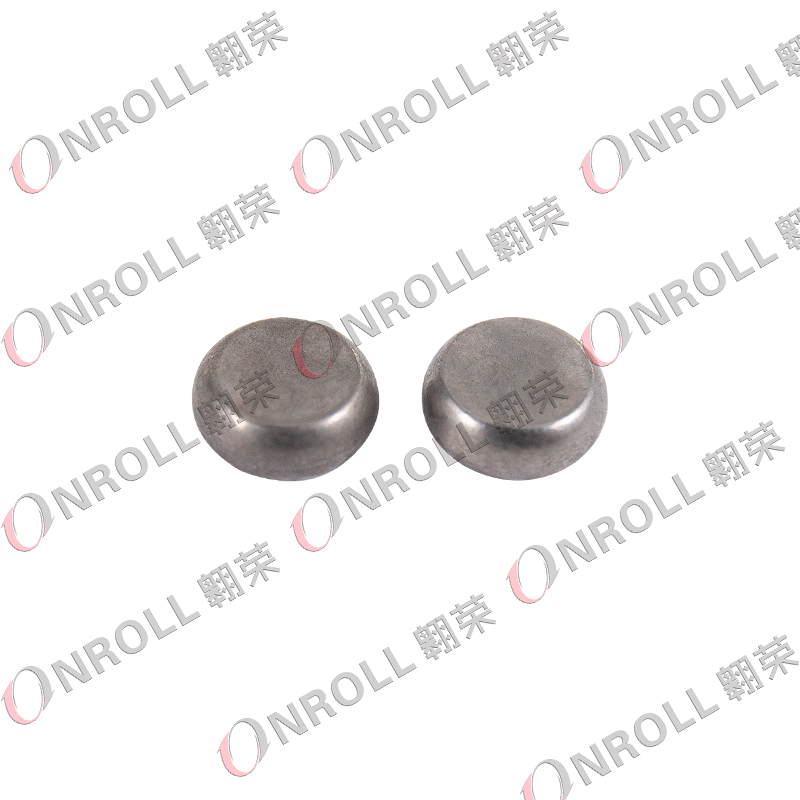

These accessories include precision components such as synchronizer struts, transmission parts, and advanced brake system parts, which help in achieving smoother gear shifts, enhanced power management, and increased energy efficiency.

The Role of Synchronizer Struts in New Energy Gearboxes

One of the most important parts in modern gearboxes, particularly in automated manual transmissions (AMTs) or dual-clutch transmissions (DCT), is the synchronizer strut. This accessory plays a crucial role in the synchronization of the gears, allowing for seamless gear transitions and preventing gear clash. For new energy vehicles, which require a more sophisticated powertrain setup, these synchronizer struts must be designed to work seamlessly with electric motor torque, which can be highly variable.

Jiaxing OnRoll Machinery Co., Ltd., a leader in producing these components, have paved the way for localizing the production of high-precision synchronizer struts. Previously dependent on imported parts, OnRoll has bridged the gap in the domestic market by producing these crucial components in China, offering an alternative to costly imports and improving overall production efficiency.

Enhancing Performance Through Advanced Transmission Parts

New energy vehicles require not just better synchronization of gears but also a robust transmission system capable of handling the unique characteristics of electric motors. **Transmission parts**, such as gear sets, shafts, and bearings, must be able to endure higher power outputs, work efficiently under low to high speeds, and handle regenerative braking systems.

As more companies like Jiaxing OnRoll Machinery Co., Ltd. focus on developing OEM/ODM solutions for these advanced systems, the demand for customized gearbox accessories is growing. These tailored solutions help optimize the performance of the gearbox, enhancing the overall vehicle efficiency and lifespan.

Brake System Parts: A Critical Accessory in New Energy Vehicles

With new energy vehicles becoming more prevalent, braking systems are also evolving. Traditional hydraulic brakes are being paired with regenerative braking systems that recover energy when the vehicle slows down. The brake system parts, such as brake discs, calipers, and pads, must be designed to handle both the physical demands of decelerating a vehicle and the electrical demands of a regenerative system.

Supporting Local Innovation and Cost Efficiency

Jiaxing OnRoll Machinery Co., Ltd. has been a significant player in driving innovation and cost reduction in the production of new energy machinery gearbox accessories. By focusing on sustained innovation and the localization of critical components, the company has made substantial strides in closing the domestic technology gap.

This approach has allowed manufacturers to reduce their dependency on imports, improving cost-efficiency for both domestic and international customers. OnRoll’s commitment to high-precision production lines ensures that their gearbox accessories meet the stringent demands of the evolving automotive industry.

Future Trends in New Energy Machinery Gearbox Accessories

As the demand for new energy vehicles continues to rise, the need for highly specialized gearbox accessories will also increase. The shift towards electric drivetr

ains, dual-clutch systems, and intelligent linear drive control systems will likely lead to further innovation in gearbox technologies. Future gearbox accessories will be designed not only for performance but also for sustainability, as automakers seek to reduce their carbon footprint throughout the supply chain.

Conclusion

The future of the automotive industry is undoubtedly electric, and with this transformation comes the increasing importance of specialized gearbox accessories. New Energy Machinery Gearbox Accessories, from synchronizer struts to brake system parts, will continue to be critical in optimizing vehicle performance, enhancing efficiency, and ensuring safety.

As technological advancements continue to shape the future of new energy vehicles, these accessories will be instrumental in driving the next generation of smart, efficient, and sustainable transportation solutions. The integration of high-quality, cost-effective, and locally produced parts will play a vital role in accelerating the widespread adoption of new energy vehicles worldwide.

English

English  Español

Español  中文简体

中文简体