What You Need to Know About Passenger Car Gearbox Parts: Functions, Innovations, and Maintenance?

Why Passenger Car Gearbox Parts Are Critical for Vehicle Performance?

The gearbox serves as the “power distributor” of a passenger car, translating engine output into usable motion through a complex interplay of components. Every shift, acceleration, and deceleration relies on the precise coordination of passenger car gearbox parts—a system where even minor wear can lead to reduced efficiency, increased fuel consumption, or complete transmission failure. Understanding these components is essential for drivers, mechanics, and industry professionals alike, as modern vehicles demand higher precision, durability, and adaptability from their transmission systems.

Core Passenger Car Gearbox Parts and Their Functions

Gear Sets: The Fundamental Power Transmitters

Gears are the most recognizable passenger car gearbox parts, responsible for adjusting torque and speed ratios. Modern transmissions use several specialized designs:

- Spur Gears: Featuring straight teeth parallel to the shaft, these are simple and cost-effective but generate more noise due to direct tooth contact. They’re often used in low-speed, low-torque applications within auxiliary systems.

- Helical Gears: With angled teeth that engage gradually, helical gears reduce noise and vibration. Their design allows for higher load capacity, making them common in main transmission pathways.

- Planetary Gear Sets: Consisting of a sun gear, planet gears, and a ring gear, this compact arrangement enables multiple gear ratios in automatic transmissions. Their nested structure allows for smooth, rapid shifts by combining different gear engagements.

- Hypoid Gears: Used primarily in rear-wheel-drive differentials, these gears offset the input and output shafts, allowing for lower vehicle profiles while handling high torque.

Each gear type undergoes rigorous engineering: tooth profiles are optimized using computer-aided design (CAD) to minimize friction, while materials like 20MnCr5 alloy steel are heat-treated to withstand cyclic loading and prevent pitting.

Synchronizers: Enabling Smooth Manual Shifts

In manual transmissions, synchronizers are vital passenger car gearbox parts that prevent grinding during gear changes. These components match the rotational speed of the incoming gear to the output shaft before engagement, using:

- Friction Cones/Rings: Typically made of brass or carbon-reinforced composites, these create controlled friction to equalize speeds.

- Blocking Rings: Prevent premature engagement until speeds are synchronized, protecting gear teeth from damage.

- Springs and Detents: Maintain pressure on the synchronizer assembly to ensure consistent performance.

Modern synchronizers are engineered to handle the higher torques of turbocharged engines, with surface treatments like molybdenum disulfide coatings reducing wear and extending service life.

Clutch Systems: Managing Power Flow

Both manual and automatic transmissions rely on clutches to connect or disconnect engine power:

- Manual Clutches: Comprising a flywheel, pressure plate, and friction disc, these use mechanical or hydraulic force to engage. Organic friction materials offer smooth engagement for daily driving, while ceramic or metallic discs provide higher heat resistance for performance applications.

- Automatic Clutch Packs: Found in torque converter transmissions, these consist of alternating friction discs (connected to the gear set) and steel plates (connected to the transmission case). Hydraulic pressure activates the packs, allowing for seamless gear changes without driver input.

Shafts and Bearings: The Backbone of Rotation

Shafts and bearings are unsung passenger car gearbox parts that ensure stable rotation under extreme loads:

- Input Shaft: Transfers power from the engine to the gear set, often splined to connect with the clutch.

- Countershaft and Output Shaft: In manual transmissions, the countershaft houses driven gears that mesh with the input shaft, while the output shaft delivers power to the drivetrain.

- Bearings: Roller and ball bearings support these shafts, reducing friction with precision tolerances (often within 5 microns). Modern designs include sealed units with lifetime lubrication to prevent contamination.

Supporting Systems in Modern Transmissions

Hydraulic Control Systems (Automatic Transmissions)

Automatic transmissions depend on hydraulic systems to actuate passenger car gearbox parts:

- Oil Pump: Driven by the engine, this generates pressure (typically 50-300 psi) to operate clutches and valves.

- Valve Body: A complex assembly of spool valves that direct fluid flow, determining which clutch packs engage based on speed, load, and driver input.

- Solenoids: Electronically controlled valves that modulate pressure, enabling precise shift timing managed by the Transmission Control Module (TCM).

Electronic Controls: Precision and Adaptability

Modern transmissions integrate electronics to optimize passenger car gearbox parts performance:

- TCM (Transmission Control Module): Processes data from sensors (speed, temperature, throttle position) to adjust shift points, pressure, and torque converter lockup.

- Speed Sensors: Monitor input/output shaft speeds to ensure proper gear engagement.

- Pressure Sensors: Maintain optimal hydraulic pressure, preventing slippage or excessive wear.

This electronic-mechanical integration allows transmissions to adapt to driving styles—sport mode holds gears longer for acceleration, while eco mode prioritizes early shifts for fuel efficiency.

Common Issues and Maintenance of Passenger Car Gearbox Parts

Typical Failure Modes

- Gear Wear: Pitting, scuffing, or tooth breakage often results from insufficient lubrication, overload, or manufacturing defects.

- Synchronizer Degradation: Worn friction rings cause grinding during shifts, a common issue in high-mileage manual transmissions.

- Clutch Slippage: In manual systems, this may stem from a worn friction disc or weak pressure plate; in automatics, it can indicate failing clutch packs or low hydraulic pressure.

- Bearing Failure: Contamination or loss of lubrication leads to noise (whining at specific speeds) and eventual shaft misalignment.

Maintenance Best Practices

- Fluid Changes: Transmission fluid lubricates, cools, and transmits hydraulic pressure. For automatic systems, replacing fluid every 60,000 miles prevents degradation that can damage passenger car gearbox parts. Manual transmissions often use gear oil, which should be changed every 30,000-50,000 miles.

- Filter Replacement: In automatic transmissions, the filter traps debris to protect the valve body and clutch packs.

- Early Diagnosis: Unusual noises (grinding, whining), delayed shifts, or fluid leaks should be addressed promptly to prevent cascading damage to other components.

Innovations Shaping the Future of Passenger Car Gearbox Parts

The automotive industry’s shift toward electrification and efficiency is driving advancements in passenger car gearbox parts:

- Lightweight Materials: Magnesium alloys and carbon-fiber composites reduce gearbox weight, improving fuel economy without sacrificing strength.

- 3D Printing: Additive manufacturing enables complex geometries, such as lattice-structured gears that reduce mass while maintaining load capacity.

- Electrified Transmissions: Hybrid and electric vehicles use specialized gear sets (e.g., single-speed reducers or multi-speed EV transmissions) with integrated motors, requiring passenger car gearbox parts to handle both mechanical and electrical loads.

- Smart Sensors: Embedded sensors in gears and bearings monitor wear in real time, transmitting data to the vehicle’s computer for predictive maintenance alerts.

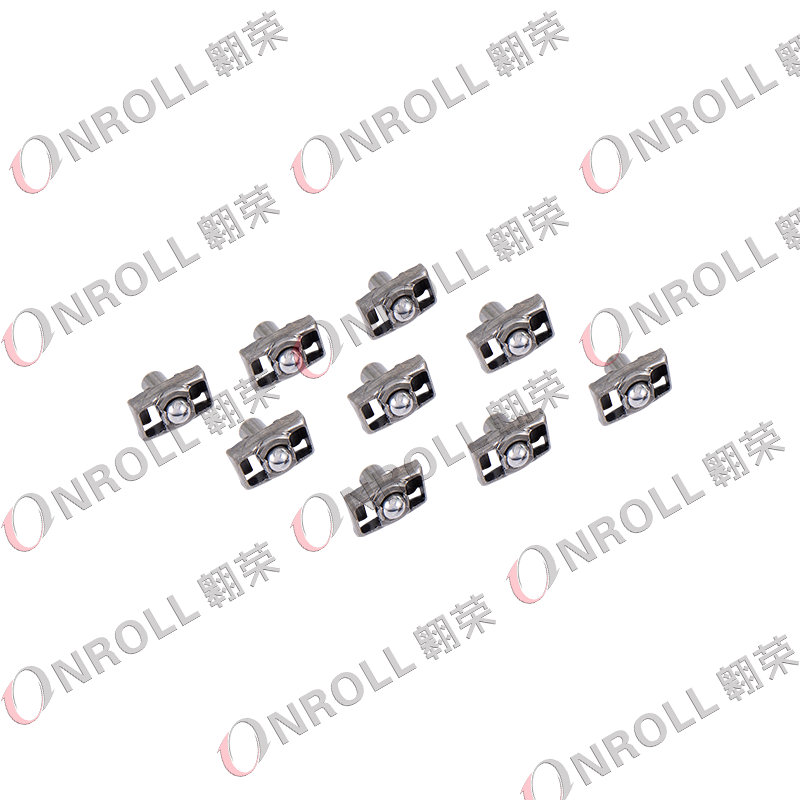

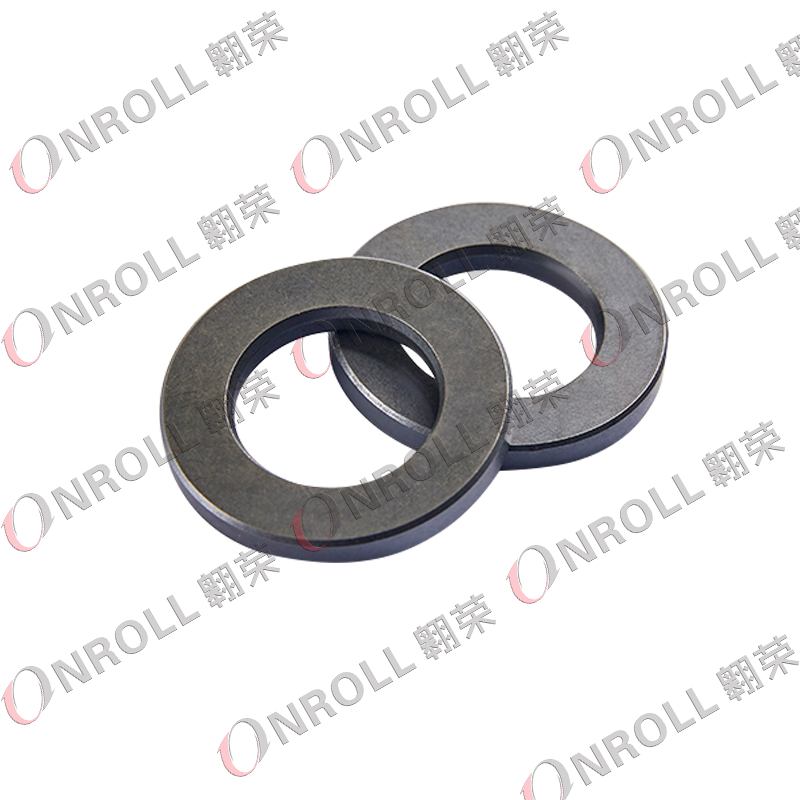

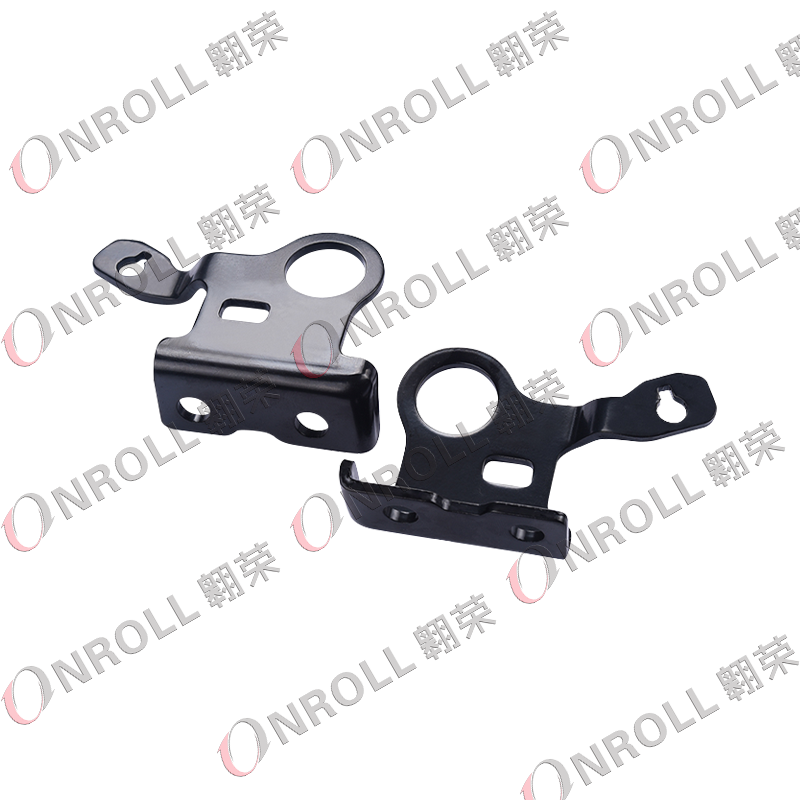

In this landscape of innovation, manufacturers like Jiaxing OnRoll Machinery Co., Ltd. are contributing by focusing on precision manufacturing techniques—such as CNC grinding with micron-level accuracy and advanced heat treatment processes—that enhance the durability and performance of critical passenger car gearbox parts. Their work reflects the industry’s commitment to balancing tradition with technology, ensuring that modern transmissions meet the demands of tomorrow’s vehicles.

Conclusion: The Importance of Understanding Passenger Car Gearbox Parts

From the simplest spur gear to the most advanced electronic control system, passenger car gearbox parts form a symphony of engineering that defines a vehicle’s performance, efficiency, and reliability. Whether you’re a driver noticing a subtle shift delay, a mechanic diagnosing a fault, or an engineer designing the next generation of transmissions, a deep understanding of these components is essential.

As vehicles evolve, so too will the passenger car gearbox parts that power them. By staying informed about their functions, maintenance needs, and technological advancements, we can ensure that transmissions continue to adapt—delivering smoother rides, better efficiency, and longer lifespans for the cars of today and tomorrow.

English

English  Español

Español  中文简体

中文简体