Product Consultation

Your email address will not be published. Required fields are marked *

Cold Heading Agricultural Machinery Parts: A Foundation for Durability

Aug 06,2025What should you know about synchronizer guide block assembly?

Aug 06,2025Why Bus Gearbox Parts Are Critical for Vehicle Performance?

Aug 06,2025Commercial Vehicle Gearbox Parts: A Comprehensive Guide to Market Trends and Maintenance

Aug 06,2025In an era where global food demand continues to rise, the efficiency and reliability of agricultural machinery are more critical than ever. From powerful tractors plowing vast fields to precision planters ensuring optimal crop yields, these machines are the backbone of modern farming. However, the components within this machinery operate under incredibly demanding conditions, constantly battling against immense wear, extreme stress, and the relentless forces of nature. The durability of each part directly impacts a machine's lifespan, operational efficiency, and ultimately, a farmer's productivity and profitability.

Addressing these challenges requires manufacturing methods that can produce components capable of withstanding such harsh environments. This is where cold heading emerges as a superior solution. Unlike traditional manufacturing processes that might compromise material integrity, cold heading is a specialized metal-forming technique that enhances the inherent strength and resilience of metal parts. This article will delve into the intricacies of the cold heading process, highlighting its significant benefits for agricultural machinery components, exploring common applications where it excels, and looking ahead at future trends that will further solidify its role in the agricultural industry.

Cold heading, also known as cold forming or cold forging, is a manufacturing process where metal wire or rod is deformed at room temperature into a desired shape using a series of dies and punches. This process contrasts sharply with hot forging, which involves heating the metal to high temperatures before forming. In cold heading, the material is forced to flow into the die cavities, undergoing plastic deformation without the need for external heat.

Several fundamental principles underpin the effectiveness of cold heading:

The unique characteristics of the cold heading process translate into significant advantages when applied to the manufacturing of agricultural machinery components, directly addressing the demanding conditions these parts face.

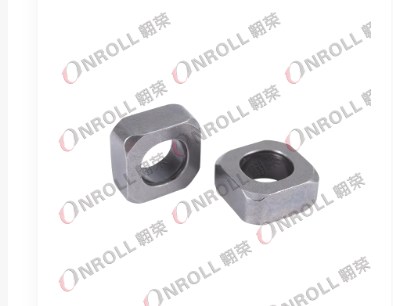

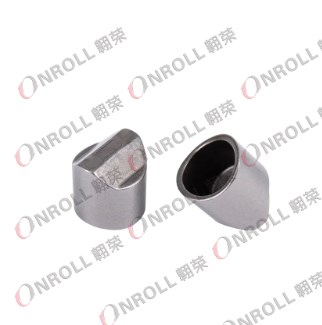

The advantages of cold heading make it an ideal manufacturing method for a wide array of components used in agricultural machinery, particularly those requiring high strength, durability, and cost-effective mass production.

Fasteners are ubiquitous in agricultural equipment, holding together critical assemblies and enduring constant vibration and stress. Cold heading is the primary method for producing many of these essential components:

Beyond standard fasteners, cold heading is increasingly utilized for more complex, application-specific parts that demand superior mechanical properties:

To illustrate the tangible benefits of cold heading in agricultural machinery, let's look at specific examples where this manufacturing process significantly enhances performance and longevity.

Plow bolts are perhaps one of the most punishing examples of components in agricultural machinery. They secure the plowshares to the plow frame, enduring immense forces as the plow cuts through compacted soil, rocks, and roots. Traditional machined bolts, with their interrupted grain flow, are susceptible to fatigue and shear failure under these conditions.

Cold-headed plow bolts, however, are engineered for this brutality. During the cold heading process, the metal's grain structure is continuously formed around the bolt's head and shank, creating an uninterrupted flow that mirrors the contours of the part. This optimized grain flow dramatically increases the bolt's fatigue resistance and shear strength. As a result, cold-headed plow bolts can absorb and distribute the impact and abrasive forces more effectively, leading to fewer breakages in the field, reduced downtime for farmers, and a longer service life for the plow itself. This direct impact on operational reliability makes cold heading the preferred method for such critical fasteners.

Agricultural machinery relies heavily on various pins – clevis pins, hitch pins, and pivot pins – to connect implements, secure linkages, and allow for articulation. These pins are constantly subjected to shear forces, bending moments, and abrasive wear as they rotate within their housings or endure the pulling and pushing of heavy loads.

Cold heading provides pins with superior mechanical properties crucial for their longevity. The work hardening effect increases the pin's surface hardness and overall tensile strength, making it highly resistant to the constant friction and wear from movement. Furthermore, the precise dimensions achieved through cold heading ensure a snug fit, minimizing play and reducing the likelihood of premature wear in the mating components. A cold-headed hitch pin, for instance, will maintain its integrity and secure connection far longer than a conventionally manufactured one, preventing costly equipment separations or failures during critical farming operations. The enhanced durability of these seemingly small components contributes significantly to the overall reliability and extended lifespan of the entire machinery.

The field of cold heading, like all manufacturing sectors, is continuously evolving, driven by advancements in materials science, automation, and the increasing demand for more efficient and sustainable production methods. For agricultural machinery parts, these future trends promise even greater performance and adaptability.

Research and development are consistently yielding new metal alloys designed specifically for cold heading. These advanced materials often possess a superior combination of ductility (for formability), strength, and specialized properties like enhanced corrosion resistance or extreme wear resistance. For agricultural applications, this means the potential for components that can withstand even harsher environments, operate at higher stresses, and last longer without needing replacement. Innovations in low-alloy steels with improved cold formability and high-strength stainless steels are particularly relevant for this sector.

The cold heading process itself is becoming more sophisticated.

Sustainability is a growing imperative across all industries, and cold heading is well-positioned to contribute positively.

These factors make cold heading an increasingly attractive option for companies committed to sustainable manufacturing practices.

The future of cold heading also involves its seamless integration with other manufacturing techniques to create highly specialized components.

These trends collectively point towards a future where cold-headed agricultural machinery parts are not only stronger and more durable but also produced with greater efficiency, precision, and environmental responsibility, further bolstering the reliability of modern farming equipment.

In conclusion, the cold heading process stands as a cornerstone in the manufacturing of high-performance agricultural machinery parts. Its ability to form metal at room temperature, aligning grain structures and inducing work hardening, yields components with superior durability, enhanced strength, and remarkable resistance to fatigue, wear, and impact. These inherent benefits directly address the severe operational demands placed on farming equipment, leading to more reliable machines and reduced downtime for farmers.

Beyond its mechanical advantages, cold heading offers significant cost efficiencies through minimized material waste and high-speed production capabilities. The precision and consistency achieved through this method ensure uniform quality across large batches, while the excellent surface finish reduces the need for costly secondary operations.

From crucial fasteners like plow bolts and hitch pins to specialized components for tillage, engine, and transmission systems, cold heading proves its versatility and indispensable role. As the agricultural sector continues to evolve, so too will cold heading, with ongoing innovations in advanced materials, process optimization, and sustainable practices. The integration of cold heading with secondary processes further expands its capabilities, ensuring that agricultural machinery parts are not only robust but also produced with increasing efficiency and environmental consciousness.

Ultimately, the ongoing evolution of manufacturing techniques like cold heading ensures the continued advancement of the agricultural sector, providing farmers with the reliable, efficient, and durable machinery they need to feed a growing world.

Your email address will not be published. Required fields are marked *

(+86)-191 0581 0729

(+86)-137 5850 1558