Product Consultation

Your email address will not be published. Required fields are marked *

Cold Heading Agricultural Machinery Parts: A Foundation for Durability

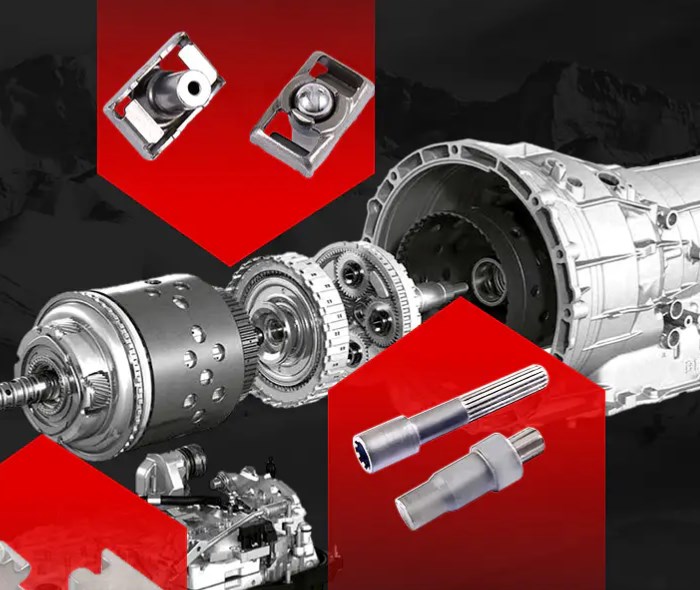

Aug 06,2025What should you know about synchronizer guide block assembly?

Aug 06,2025Why Bus Gearbox Parts Are Critical for Vehicle Performance?

Aug 06,2025Commercial Vehicle Gearbox Parts: A Comprehensive Guide to Market Trends and Maintenance

Aug 06,2025As the core power unit of modern machinery and transportation, the performance and lifespan of the engine directly depend on the design, material selection, and manufacturing precision of its various key components. Whether in automobiles, industrial machinery, or marine power systems, the technological level of engine components determines the overall efficiency, stability, and durability of the machine.

Engine Block and Cylinder Head: Structure and Heat Dissipation Performance

The engine block is the fundamental structure of the entire powertrain. It not only bears the movement of the piston and crankshaft but also transmits power and supports various auxiliary devices. Modern engine blocks are mostly made of aluminum alloy or high-strength cast iron to balance strength, heat dissipation, and weight control. The design precision of the cylinder block directly affects combustion efficiency and engine life, while the arrangement of internal cooling channels is crucial for heat dissipation performance.

The cylinder head, located above the cylinder block, is an important part of cylinder sealing and combustion control. Its internal structure includes valves, valve seats, and the combustion chamber, directly affecting the engine's airflow passages and combustion efficiency. With the development of turbocharging technology, the materials and processing techniques of high-performance engine cylinder heads are constantly being optimized to meet the demands of high compression ratios and high-temperature operating conditions. Piston and Connecting Rod: The Core Hub of Power Transmission

The piston is the load-bearing component directly subjected to the pressure of combustion gases within the engine. Its mass, shape, and material all affect the engine's dynamic performance. Lightweight pistons reduce reciprocating inertia and improve engine response speed, while high-strength alloy pistons maintain a stable shape under high temperature and pressure conditions, ensuring reliable operation.

The connecting rod connects the piston and crankshaft, and is a key component in converting the linear motion generated by combustion into rotational motion. The strength, rigidity, and fatigue resistance of the connecting rod directly determine the engine's stability under high speed and high load. In modern engines, connecting rods are mostly made of forged steel or high-strength aluminum alloy, achieving a balance between lightweight and high durability through optimized cross-sectional shape and surface treatment processes.

Crankshaft and Flywheel: Power Output and Balance Control

The crankshaft is the core shaft for power transmission in the engine. It bears the rotational motion of the piston and connecting rod and transmits power to the transmission system. The crankshaft is typically made of high-strength steel or cast iron, and its wear resistance and fatigue resistance are improved through heat treatment and precision machining. The weight distribution and dynamic balance of the crankshaft directly affect engine vibration and noise levels, making it a crucial factor in engine design.

The flywheel, as an extension of the crankshaft, not only stores rotational energy for smooth power output but also reduces engine vibration at low speeds. Optimization of flywheel materials and structure also impacts engine starting performance and transmission smoothness.

Valve and Camshaft: Gas Flow and Timing Control

The valve system, including intake and exhaust valves, is a key component controlling the inflow and outflow of combustion gases in the engine. Valve sealing, high-temperature resistance, and response speed directly affect combustion efficiency and exhaust emissions. With the widespread adoption of turbocharging and high-efficiency combustion technologies, high-performance valve materials and surface treatment processes are continuously being upgraded to meet higher operating conditions.

The camshaft controls the opening and closing timing of the valves, achieving optimal intake and exhaust efficiency through precise profile design. The manufacturing precision and friction performance of the camshaft directly affect the engine's power output curve and fuel economy. Modern engines often employ lightweight materials and rolling or hydraulic tappet mechanisms to improve overall performance.

Lubrication and Cooling Systems: Ensuring Operational Stability

The efficient operation of engine components relies heavily on the support of lubrication and cooling systems. The lubrication system uses circulating engine oil to lubricate moving parts such as the crankshaft, connecting rods, and pistons, reducing friction and wear. Modern engine lubrication technologies include high-performance synthetic oils and high-pressure injection lubrication to meet durability requirements under high-speed, high-load conditions.

The cooling system controls engine temperature through water or oil cooling to prevent overheating that could lead to component deformation or damage. The design of cooling channels in the cylinder block and cylinder head, radiator arrangement, and coolant flow control are all key factors ensuring long-term stable engine operation.

As the foundation of the power system, engine components not only determine the overall engine's performance and lifespan but also reflect a high degree of integration between mechanical engineering and materials science. From the cylinder block and pistons to the crankshaft and valves, each component embodies complex design concepts and precise manufacturing techniques. With technological advancements and increasingly stringent environmental regulations, the optimization and innovation of engine components will continue to lead the development trend of power systems, providing more efficient and reliable power for vehicles and machinery.

Your email address will not be published. Required fields are marked *

(+86)-191 0581 0729

(+86)-137 5850 1558