Product Consultation

Your email address will not be published. Required fields are marked *

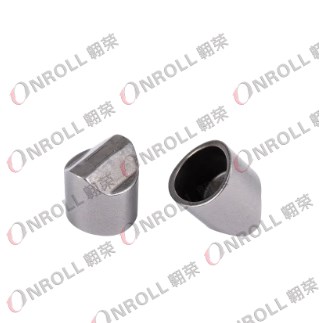

Cold Heading Agricultural Machinery Parts: A Foundation for Durability

Aug 06,2025What should you know about synchronizer guide block assembly?

Aug 06,2025Why Bus Gearbox Parts Are Critical for Vehicle Performance?

Aug 06,2025Commercial Vehicle Gearbox Parts: A Comprehensive Guide to Market Trends and Maintenance

Aug 06,2025In the development of modern agriculture, the level of mechanization is constantly increasing. As the core components of machinery operation, the performance of agricultural machinery parts directly affects the efficiency and quality of agricultural production. From tractors to harvesters, from tillers to spraying equipment, every piece of agricultural machinery relies on high-performance, durable parts. With the increasing demands for efficiency and precision in agriculture, the research and application of agricultural machinery parts are gradually moving towards high precision, high wear resistance, and intelligentization.

Agricultural machinery parts are not only the "skeleton" and "muscle" of the machinery, but also the key to ensuring its long-term stable operation. Each part, from its structural design to material selection, directly affects the overall operating efficiency and reliability of the machine. Gears, bearings, transmission chains, and hydraulic components in the drive system are responsible for power transmission and load adjustment; working parts such as blades, buckets, and plows are in direct contact with the soil and crops, and their wear resistance and strength are key factors in ensuring operational accuracy.

At the same time, the precision manufacturing and surface treatment technologies of parts are receiving increasing attention. High-precision components can reduce resistance during mechanical operation, decrease energy consumption and failure rates, thereby extending the overall service life of the machine. In high-temperature, high-humidity, or dusty agricultural operating environments, the corrosion resistance and wear resistance of components are particularly important. This not only affects operational efficiency but also directly determines the cost and cycle of machine maintenance.

The choice of materials for agricultural machinery components directly affects their performance and lifespan. With technological advancements, traditional steel, cast iron, and alloy materials are being developed towards high-strength alloy steel, composite materials, and surface-strengthened materials. Through the application of heat treatment, surface coating, and coating technologies, components have achieved significant improvements in wear resistance, corrosion resistance, and load-bearing capacity.

Simultaneously, the introduction of precision machining and intelligent manufacturing technologies ensures the dimensional accuracy and structural consistency of components. The application of CNC machining, laser cutting, and high-precision casting technologies not only improves the reliability of components but also shortens the production cycle. For some high-load components, the use of composite materials and advanced surface treatment technologies can effectively reduce wear and fatigue, ensuring the stability of agricultural machinery during long-term, high-intensity operation.

Component design is a crucial bridge connecting mechanical performance and operational efficiency. A scientifically sound component design not only ensures the structural stability of the machinery but also optimizes energy transmission paths and improves power utilization efficiency. Taking the drive system as an example, the gear tooth profile design, bearing load distribution, and optimized transmission chain structure directly determine the smoothness and durability of power transmission during operation.

Regarding operating components, the geometry and material selection of blades, plows, and harvesters also significantly impact operational accuracy. Precisely designed components can reduce crop damage, improve soil tillage uniformity, and lower energy consumption. As modern agriculture demands increasingly higher operational efficiency and precision, the scientific and innovative nature of component design has become a key factor in enhancing the overall competitiveness of the machinery.

Wear, corrosion, and fatigue are inevitable in agricultural machinery components during long-term use; therefore, scientific maintenance and lifespan management are essential. Regularly inspecting component wear and promptly replacing or repairing key components can effectively reduce the overall machine failure rate and ensure operational continuity. Meanwhile, using high-performance lubricants, reasonable load operation, and protective measures can also extend the service life of components.

The future development of agricultural machinery components will focus more on high performance, lightweighting, and intelligence. New high-strength materials, surface treatment technologies, and composite processes will continuously improve the wear resistance and service life of components. At the same time, the integration of intelligent monitoring and automatic adjustment systems makes components not only the execution units of machinery but also the core of data-driven, efficient operation.

With the development of precision agriculture and smart agriculture, components place higher demands on the stability, reliability, and high-precision operation capabilities of machinery. The optimized design, manufacturing process, and material innovation of each component will directly affect the competitiveness and operating efficiency of the entire machine.

High-precision manufacturing ensures a tight fit between components during machine operation, reducing friction loss and energy waste, extending service life, and improving operating efficiency and stability.

Materials directly determine the wear resistance, corrosion resistance, and strength of components. Choosing high-strength alloys or composite materials can significantly improve durability and overall machine performance.

Through proper maintenance, regular inspections, scientific lubrication, and load management, the service life of components can be significantly extended. Intelligent monitoring technology can also provide early warnings of faults, enabling predictive maintenance.

Your email address will not be published. Required fields are marked *

(+86)-191 0581 0729

(+86)-137 5850 1558