Product Consultation

Your email address will not be published. Required fields are marked *

Cold Heading Agricultural Machinery Parts: A Foundation for Durability

Aug 06,2025What should you know about synchronizer guide block assembly?

Aug 06,2025Why Bus Gearbox Parts Are Critical for Vehicle Performance?

Aug 06,2025Commercial Vehicle Gearbox Parts: A Comprehensive Guide to Market Trends and Maintenance

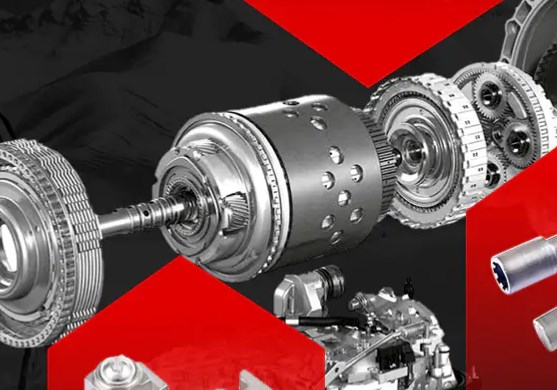

Aug 06,2025Transmission components play a crucial role in mechanical transmission systems. As an indispensable part of industrial equipment, transmission components are involved in the transfer of energy and motion from the power source to the working mechanism. Their efficient operation directly affects the performance and stability of the entire system. With the continuous development of technology, the design, materials, and manufacturing processes of transmission components are undergoing significant changes, leading to their widespread application in various industries.

There are many types of transmission components, but their core function remains the same – to transmit power and motion. Common transmission components include gears, couplings, bearings, belts, and chains. Each component plays a different role in specific applications, but they are all part of the transmission system, working together to ensure the equipment operates normally.

Gears are one of the most common transmission components. They transmit power from one component to another through the meshing of teeth, changing the direction or speed of motion in the process. Different types of gears, such as spur gears, helical gears, and worm gears, are suitable for different transmission needs.

Couplings are mainly used to connect two shafts, transmitting torque through the rotation of the coupling and eliminating shaft misalignment. The design of the coupling must not only ensure the efficiency of power transmission but also minimize the impact of vibration and shock on the system.

Bearings are key components that support and guide rotating parts. They reduce friction between moving parts, improving the overall efficiency of the transmission system. Different types of bearings, including rolling bearings and sliding bearings, have different advantages in terms of load capacity, wear resistance, and operating speed.

Belts and chains are suitable for transmitting high-power power. They transmit power through friction or chain connections. Compared with gear transmission, belt and chain transmission methods are more flexible and can absorb load changes in the mechanical system within a certain range.

With the development of the mechanical industry, the materials and manufacturing processes of transmission components are constantly being updated. Traditional steel materials are still the main materials for many transmission components, but with the increasing demand for high efficiency and high durability, various new materials are gradually being put into use. For example, gears are often manufactured using alloy steel or high-strength steel materials to improve their hardness and wear resistance. Furthermore, with the rise of lightweight design trends, some transmission components are beginning to use materials such as aluminum alloys and plastics to reduce the overall weight of the machine and improve energy efficiency. For high-speed gears, ceramic materials are becoming a research hotspot due to their extremely high hardness and excellent wear resistance.

In terms of manufacturing processes, the application of CNC technology has brought the machining accuracy of transmission components to a new level. Through precision machining, the meshing accuracy of gears and the dimensional tolerances of bearings can be effectively controlled, thereby improving the reliability and stability of the entire system.

Transmission components have widespread applications in various industries, whether in traditional fields such as mechanical manufacturing, automotive, and aerospace, or in modern industries such as robotics, energy, and electronic equipment. Transmission components play a crucial role in all of them.

In the automotive industry, the transmission system is the core of vehicle power transmission, involving the coordinated operation of multiple components such as the engine, gearbox, and drive shaft. The vehicle's power system must ensure smooth and continuous operation under different working conditions; therefore, the quality and precision requirements for transmission components are extremely high.

In the field of robotics, transmission components place even greater emphasis on precision and flexibility. Due to the complexity of robot motion and the high demands on response speed, transmission components need to possess extremely high dynamic performance and low energy loss. Therefore, the combination of servo motors with precision gears and reducers has become standard for high-end robot manufacturing.

In wind power generation and other energy industries, transmission components play a key role in converting wind energy, solar energy, etc., into mechanical or electrical energy. Especially in wind turbine generators, the reliability of the transmission system directly affects power generation efficiency and maintenance costs, thus requiring even stricter requirements for transmission components.

The reliability of transmission components is fundamental to ensuring the long-term stable operation of mechanical systems. Because these components usually operate in relatively harsh environments, such as high temperature, high pressure, impact, and vibration, their design and material selection need to effectively address these challenges.

Regular maintenance and inspection are key to extending the service life of transmission components. For components such as gears and bearings, timely lubrication and cleaning are effective ways to prevent excessive wear and failure. Modern transmission systems also widely utilize intelligent monitoring technology, which can monitor the operating status of components in real time and provide early warnings based on data feedback, allowing for repairs before failures occur. This greatly improves the reliability and efficiency of the system.

Transmission components in a mechanical system are primarily responsible for converting the output of the power source into mechanical motion and transmitting this motion to other working parts. They play a role in bearing, connecting, transmitting, and regulating the system, and are fundamental to the efficient operation of the entire system.

When selecting transmission components, the main factors to consider include the load they can handle, operating speed, temperature environment, and service life. At the same time, cost, space limitations, and maintenance difficulty should also be considered.

The key to improving the service life of transmission components lies in selecting appropriate materials, designing a reasonable structure, and performing regular lubrication and inspection. In addition, using advanced intelligent monitoring technology can help detect potential problems in a timely manner, allowing for repairs in advance.

Regularly checking the wear of transmission components, promptly replacing damaged parts, and maintaining cleanliness and lubrication can effectively extend the service life of transmission components. At the same time, the system's vibration and noise should be regularly monitored to prevent further failures caused by component damage.

Gear drives are suitable for efficient and precise power transmission, especially in high-load, high-speed applications. Belt drives offer better flexibility and noise control capabilities and are suitable for medium-to-low load transmission applications. In addition, belt drive systems are generally less expensive, but gear drives typically have higher efficiency.

Your email address will not be published. Required fields are marked *

(+86)-191 0581 0729

(+86)-137 5850 1558